The GDT-EH series is a grab dredging crane aimed at improving fuel consumption.

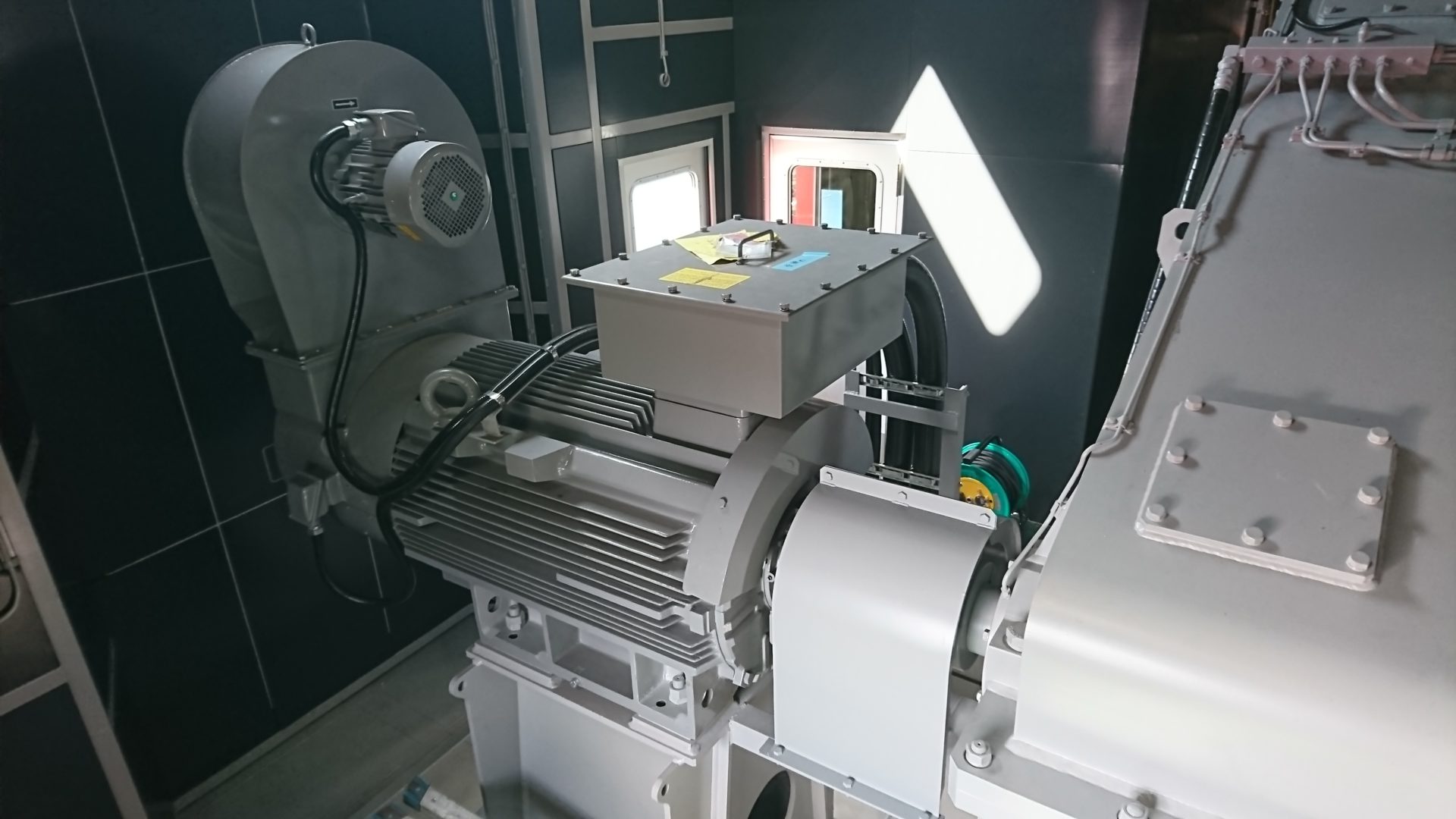

By storing the energy while grab falling as assistant energy is reused at the time of winding up grab bucket.

It is achieved to reduce the emissions of exhaust gas and CO2.

The cranes of this model have more powerful ability to do dredging work than the GDT-K series while improving fuel efficiency.

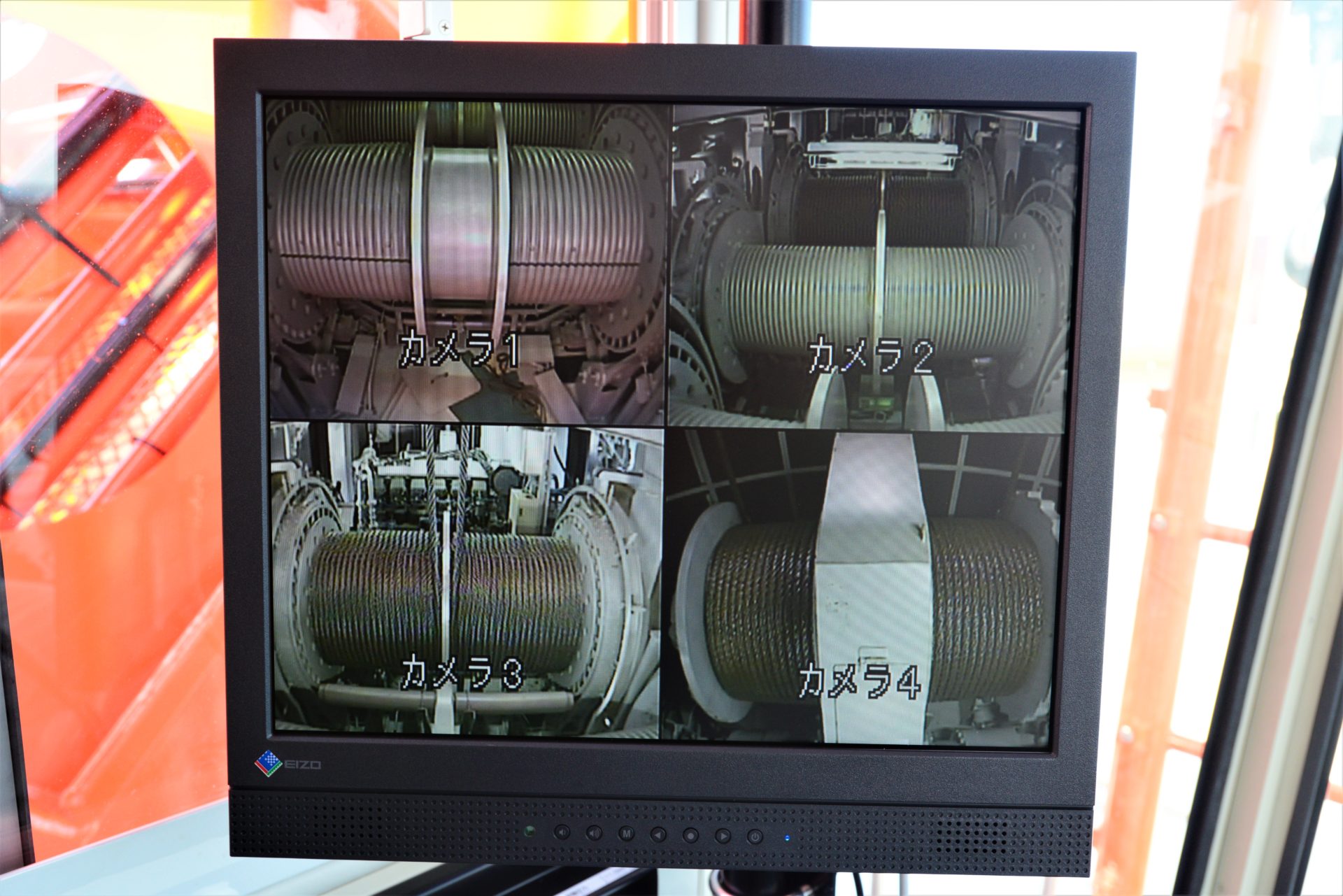

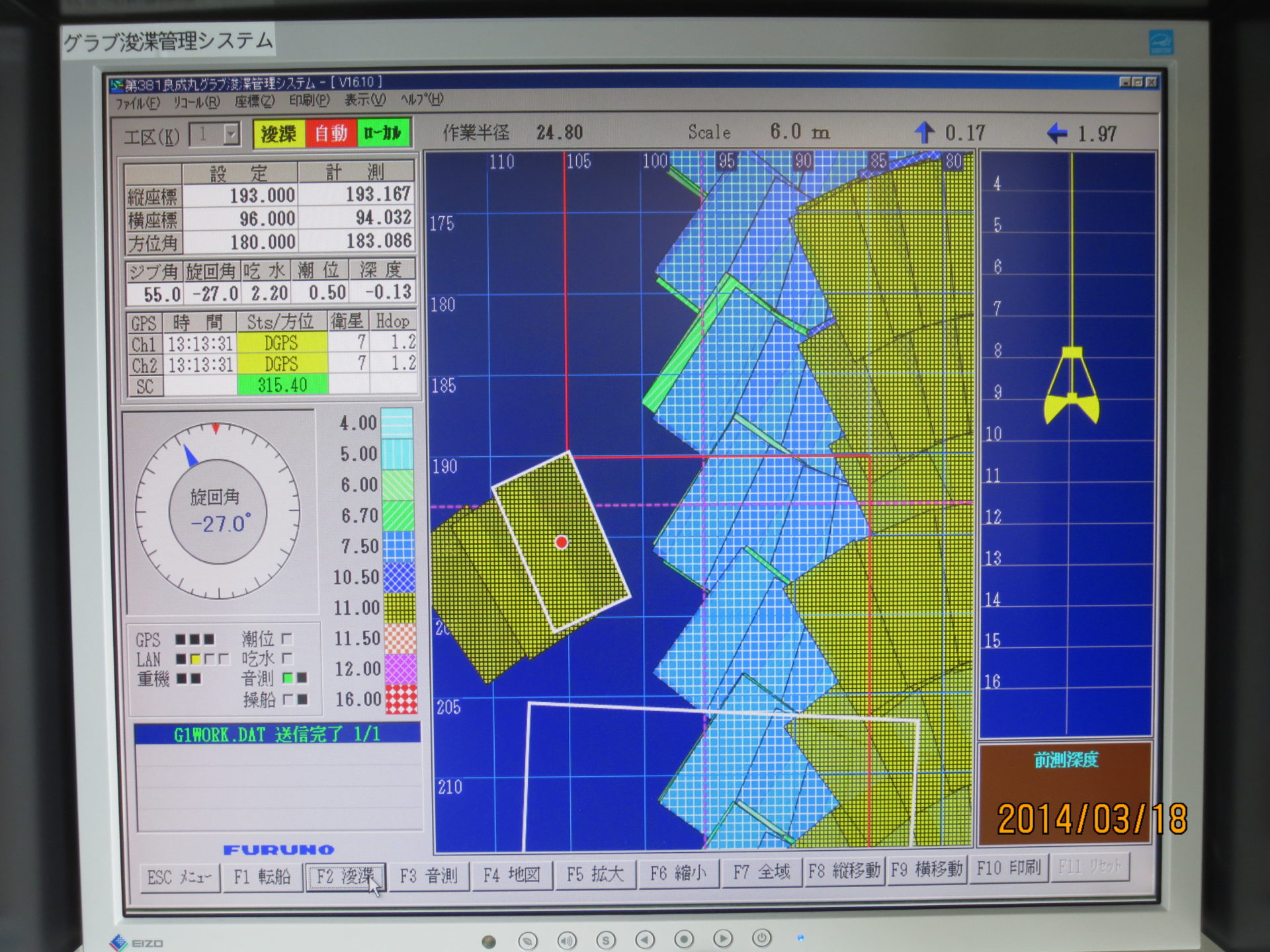

They fully display its power to dig the sand and earth of the sea bottom in the dredging work and developing route for the ship access to the port.

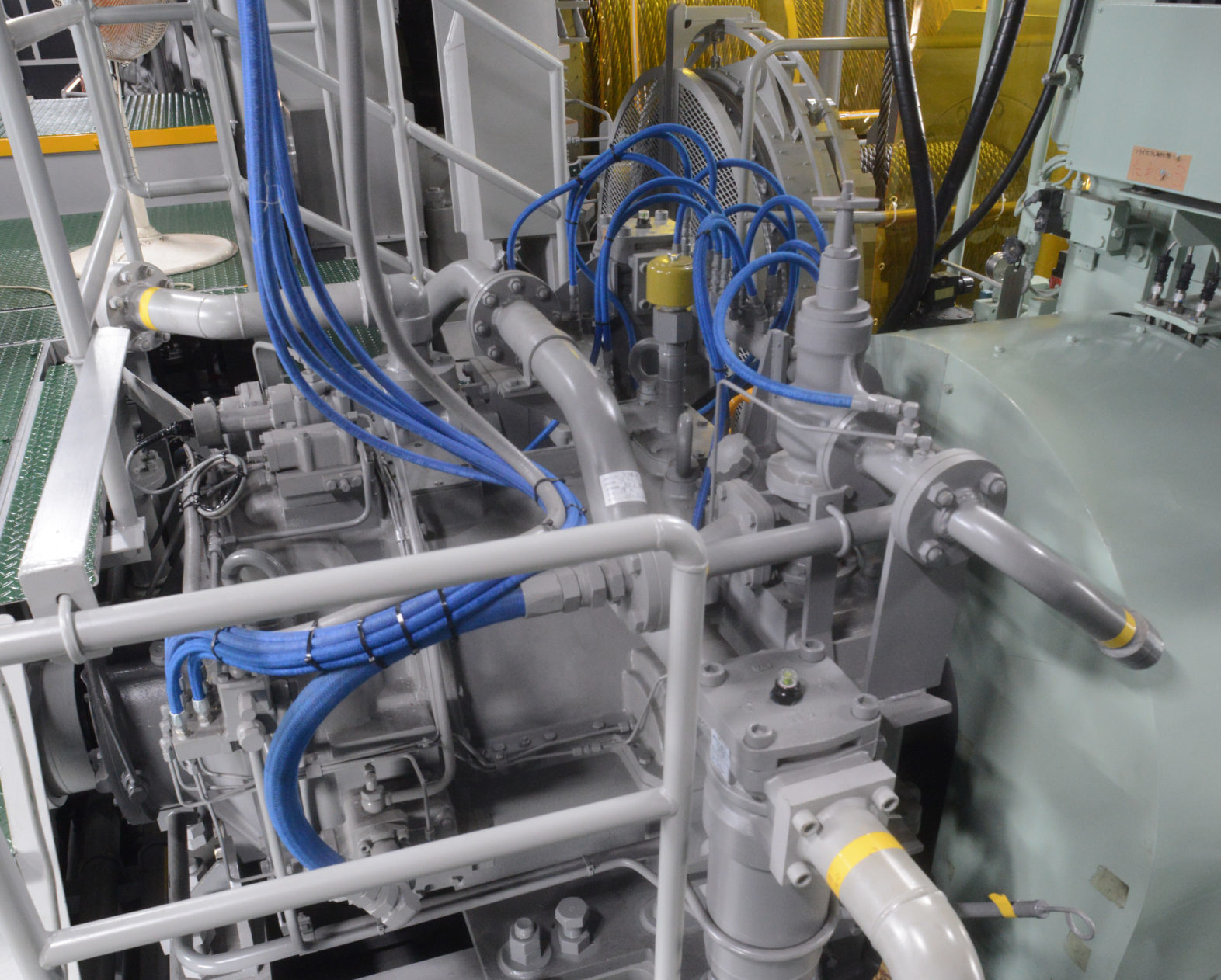

We are proud of the strength and safety of the cranes that can withstand the sever sea environment, and they are active in various parts of Japan.

Designs and manufactures are all made-to-order, designed one by one according to the customer’s requirements and construction requirements.