Maintenance

Maintenance

SKK offers maintenance support to all customers using our cranes for safe

and secure use. Send your inquiry for spare parts supply, maintenance &

repair support, and inspection by SKK technical engineers.

For Spare Parts, Maintenance

& Repair support

& SKK inspection

※对于希望用中文进行交流的客户,我们将会把我们的合作伙伴介绍给您。

Inspections and Maintenance

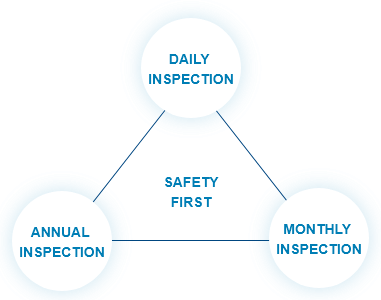

Periodical crane inspection and maintenance is essential for safe work.

Abrasion and deterioration from usage and aging could cause trouble. Regular inspection and maintenance are required to find abnormalities earlier, which minimizes trouble and leads to extend the machine’s lifespan.

In order to maintain the crane performance, inspection and

maintenance including refueling and replacement of consumables by clients are necessary.

Overall inspection by SKK Technical Engineers is available.

Daily, monthly, and annual inspections by clients are essential. Inspection details shall be referred to the operation manuals for each device. Comprehensive crane inspections by SKK technical engineers are also available. We recommend regular overhauls for engines and torque converters as well. For more details, please feel free to contact us.

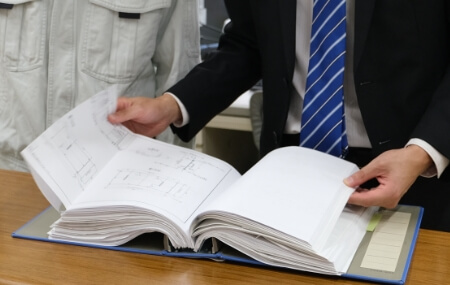

Operation Manuals

Operation manuals and parts list for cranes (Japanese) are available for most of our cranes. It includes instruction manual, inspection and maintenance details, list of oil and grease, and wire rope specification. (Paid)

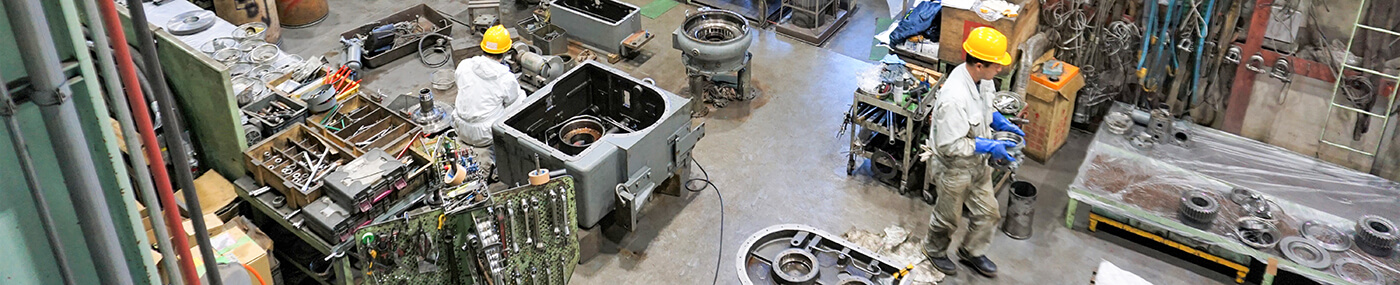

Overall Inspection by SKK Technical Engineers

SKK technical engineers are available to provide a comprehensive inspection and repair service on site depending on the locations and situations.

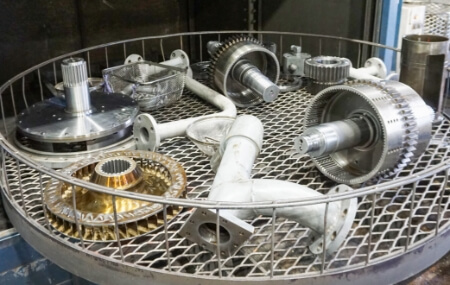

Overhaul (Engine and Torque converter)

The performance of engines and torque converters is gradually deteriorated due to aging and abrasion. On the overhaul, the engine (or converter) is disassembled, cleaned, provided with new parts for replacement, and reassembled again. We recommend periodical overhaul in order to maintain the best performance.

General guide for overhaul period

- Torque converter :

- 4,000 operation hours or every 4 years whichever comes first.

- Engine :

- 8,000 operation hours for the first time, and every 6,000 hours afterwards.

Machine and Parts Maintenance (Example)

We welcome to send parts needed as a result of crane inspections and maintenance. All parts SKK supplies are genuine parts.

Genuine parts with high quality are recommended to maintain performance and prevent troubles.

Notes

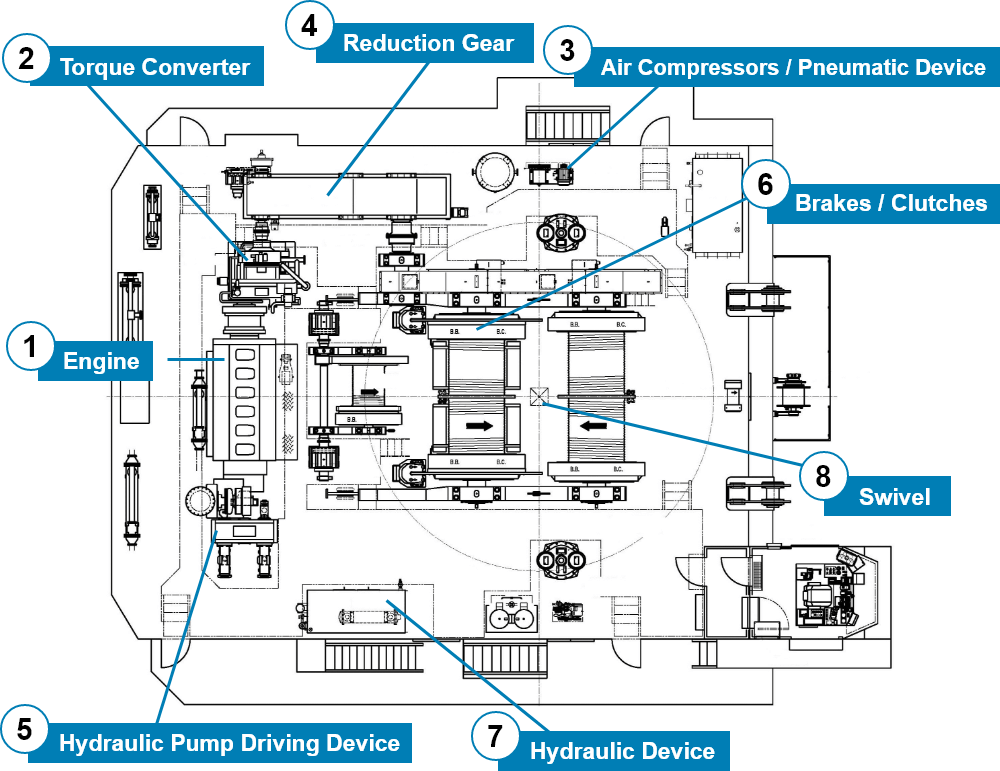

*The following shows examples of a SKK crane. Not all replacement parts are shown below. Refer to the operation manuals for details, as the devices, the layout, and the replacement parts differ for each crane.

*For replacement parts and recommended period to replace, refer to the operation manuals of each crane and the result of the inspection accordingly.

*Spare parts for aged cranes may not be available.

*Inspection and maintenance shall be carried out for safe use, but it would not guarantee the operation quality and efficiency.

1Engine

Engine is one of the most important devices. In addition to daily inspection, Overhaul is recommended after 8,000 operation hours for the first time and every 6,000 hours afterwards.

Spare parts

-

Filter Element

(Mitsubishi) -

LO Governor Filter Element

-

Zinc for Cooler

-

V-belt

-

Tachometer

-

Pressure Switch

-

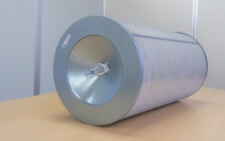

Air Filter

-

Alternator (Dynamo)

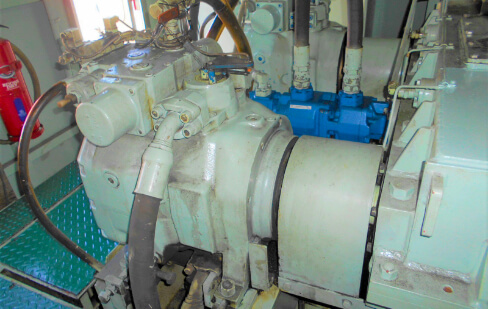

2Torque Converter

Torque converters are key to control the speed of the hook and the bucket. Torque converter malfunctions are directly linked to lower work efficiency. In addition to daily inspection, Overhauls is recommended as well. The general guide for overhaul period is every 4,000 operation hours or every 4 years, whichever comes first

Spare parts

-

Filter Element

-

Zinc for TC Oil Cooler

-

Bearing

-

Fiber Plate

-

Steel Plate

-

Sinter Plate

3Air Compressor / Pneumatic Device

Pneumatic device malfunctions cause troubles of the brakes and the clutches.

Spare parts

-

V-belt

-

Dryer Agent Kit

-

Air Chamber

-

Air Cylinder

-

Unloader Valve

-

Quick Exhaust Valve

-

Blake Valve

-

Pressure Gauge

-

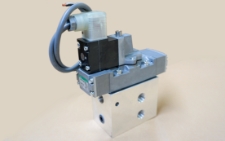

Solenoid Valve (Air)

-

Suction Air Filter

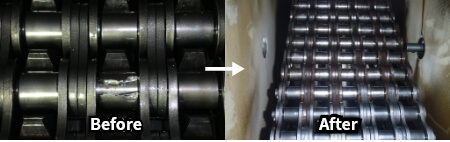

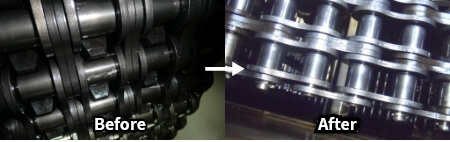

4Reduction Gear

Reduction Gear controls the drum’s movement. Power may not be transmitted due to damage in the chains.

Spare parts

-

Chain for Reduction Gear

-

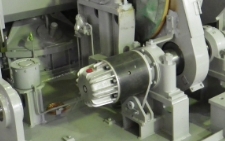

5Hydraulic Pump Driving Device

The hydraulic pump is essential for the movements such as slewing and jib luffing. Inspection of the chains, cleaning of the lubrication pump strainer is also required to avoid trouble during operation.

Spare parts

-

Hy-vo chain

-

Bearing

-

Oil Seal

-

Pressure Switch

6Brake / Clutch

For marine crane, abrasion of the lining would cause the drum to slip and the troubles in winding the wire ropes. The frequent use of clutch leads to more abrasion of the lining. Serious abrasion would cause damage to the clutch shoe.

Spare parts

-

Lining

-

Blake Band

-

Clutch Band

7Hydraulic Device

As the movements of slewing and jib luffing are operated with the hydraulic device, its malfunctions cause troubles in these movements. Cleaning of the suction filter and Refueling oils are also required other than replacement of the line filters and return filters

Spare parts

-

Line Filter

-

Return Filter

-

Zinc for Oil Cooler

-

Solenoid Valve

-

Pressure Switch

8Swivel

The swivel supplies cooling water to the crane. Lack of maintenance may cause leakage of cooling water due to corrosion. Applying greasing frequently is required

Spare parts

-

Zinc

-

O-ring

-

Casing

-

Rotary Shaft

Others

Cam clutches are used for small type of marine cranes. The required replacement period of cam clutch oil (ATF Oil) is every 6 months and the cam clutch itself is every 4 years.

When the sheave grooves are worn out about 5 mm~8 mm, replacement of the sheaves are required.

Replacement of pendant ropes is required every 10 years, though it depends on the specification.

Standard electric parts are generally recommended to be replaced every 10 years .

-

Cam Clutch

-

Cam Clutch

-

Sheave

-

Sheave Groove(Abrasion)

-

Pendant Rope

-

Pendant Rope(Locked Coil)

-

Sequencer

-

Sequencer

-

Sequencer

-

Amplifier

-

Relays

-

Relays

-

DC Power Supply

-

DC Power Supply

Records of Maintenance & Repair (Overseas)

We provide repair services and supply parts to over 30 countries, mainly in Asia.

-

Model:1800DT-K Made in 2009

Jib extention work and comprehensive inspection. The moment limiter was also adjusted following to the extention.

June 2018 Australia -

Model:20018GDT-F Made in 1992

The torque converter was low performed because of the blades were bended and iron powder was mixed in the oil. Disassembled the parts for maintenance, exchanged inner parts, then trial run.

September 2018 Philippines -

Model:20018GDT-F Made in 1990

Crane inspections, repaired scratch and other adjustments was implemented. Crane operation guidance was also provided.

December 2018 Singapore -

Model:25010GDT-F Made in 1993

The Hook was unable to be hoisted due to the mulfunction of torque converter. Pressure adjustment, parts replacement, trial run and maintenance guidance were implemented.

January 2019 Indonesia -

Model:13010GDT-002 Made in 1974

Inspection and parts replacement was implemented since bucket was unable to open/close.

January 2019 China -

Model:20018GDT-F Made in 1991

Inspection and cable processing were implemented since the signal of the depth control device has communication failure.

January 2019 China

For Spare Parts, Maintenance

& Repair support

& SKK inspection

※对于希望用中文进行交流的客户,我们将会把我们的合作伙伴介绍给您。