The GT series are marine cranes that are effective in dredging service that dig sand and soil on the bottom of the sea. In port and civil engineering project, they are used to dredge sand and soil with grab on the bottom of the sea so as to create a port. We are proud of the strength and safety that can withstand the sever sea environment, they are active not only in Japan but also overseas. Design and manufacture are all carried out based on order, the product is designed one by one according to the customer’s request and the content of the construction.

- Product

- Grab Dredging

- GT Series / Grab Dredging Crane

GT Series / Grab Dredging Crane

![]()

Equipped with an Economical High-Power Engine, Powerful Dredging Service is Possible. Line-Up up to 160t Line-Pull Force.

| Product Name | GT Series |

|---|---|

| Main Uses | Mainly used for dredging service for route and berth, also able to be customized to multi-purpose types of rock-breaking and load lifting service |

| Example of Customization | By attaching with hook, load lifting service is available. |

Features

Dredging Operation with High Accuracy and Efficiency

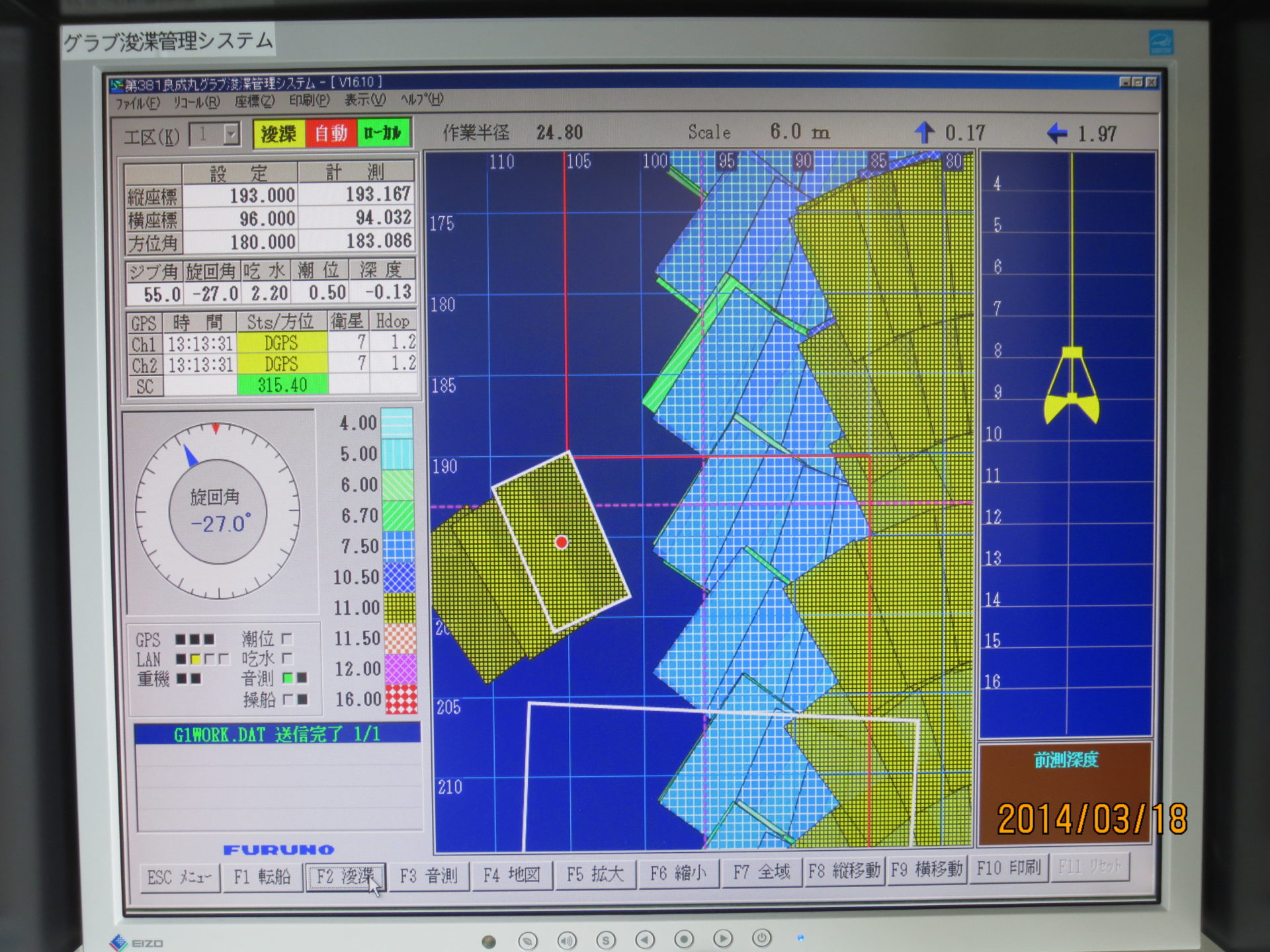

The GPS Grab Dredging Engineering Management System facilitates the dredging work by watching dredging spot and depth at the sea bottom where is difficult to visually check. The working progress is recorded by the system, that will navigate the way for dredging next time and this may help the work undergoing without waste. In addition, the flat-dredging control system allows greatly to reduce dredging sediment residue and the feature of depth meter helps dredging work at an accurate specified depth, makes the work more efficient.

Vibration and Noise Countermeasures to Reduce Operator Fatigue and Burden

An independent anti-vibration system for operator’s cab is adopted by putting anti-vibration rubber between the machine body and the operator’s seat, in this way to minimize the vibration of the machine body transmitting to the operator’s seat. Compared to conventional cranes, operator’s fatigue and burden is much more lightened. Additionally, by providing enough soundproofing, operator can have a conversation without stress even while working in the crane.

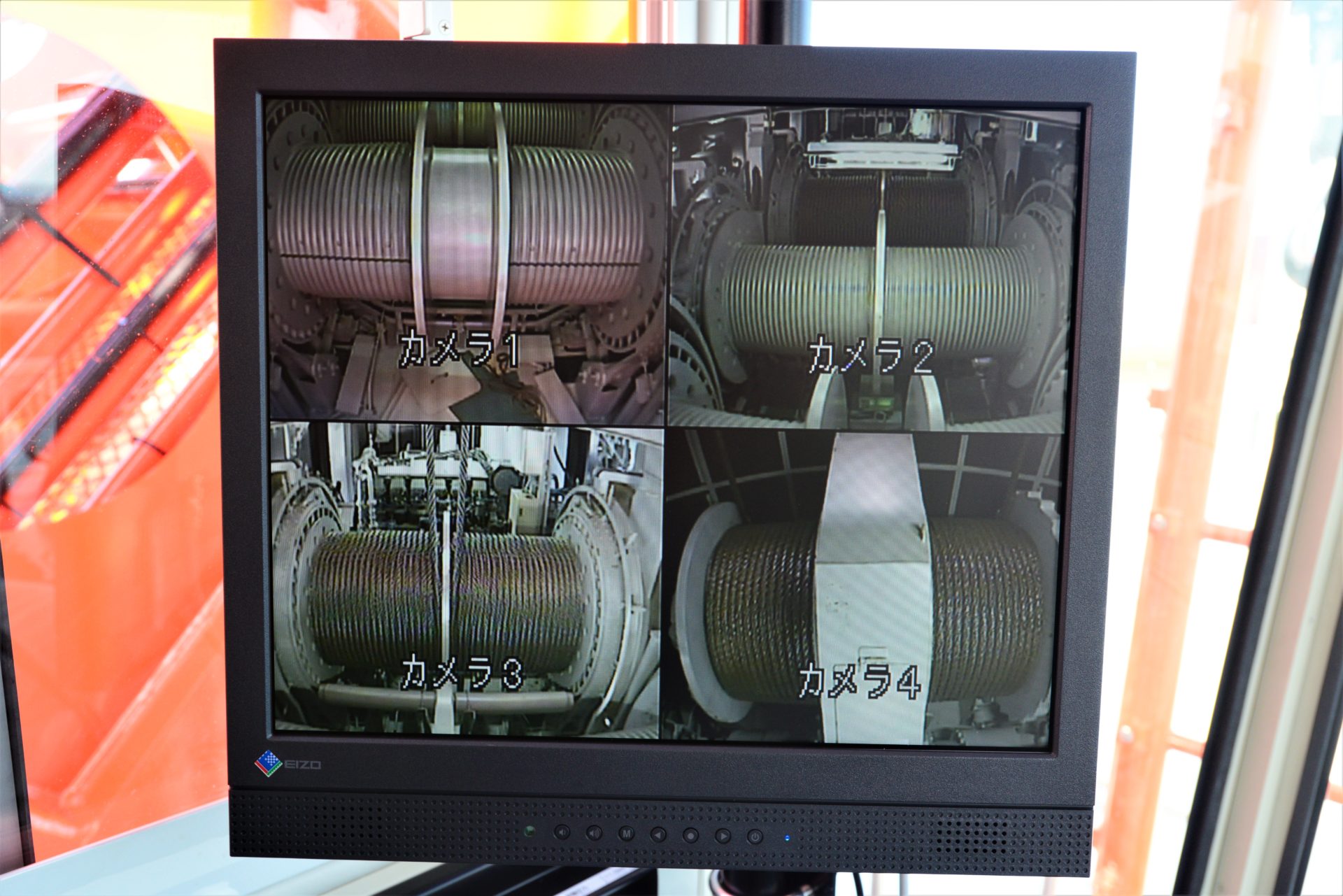

Surveillance Cameras, Sensors and Alarm Devices to Ensure Safety

Surveillance cameras are equipped over the drums so as to help operator watch the winding status of the wire rope. In addition, various devices are installed to ensure safety, such as the alarm that reacts to each over-hoisted and overload, and the stop slewing function by the sensor installed on the foldable stairs for boarding crane.

Simple Operation to Open and Close the Grab Bucket Smoothly

By putting the hoisting and open-closing operation levers in the clutch position, only with one control lever it is carried out to wind up and lower down the grab bucket easily. Moreover, the grab bucket opening degrees meter helps operator understand grab bucket opening degrees within from 0% to 100% in real time.

Set to an Easy-to-Use Operating Environment for Operators

Various control such as torque converter in speed control mode or torque control mode, and various operation of crane movement can be adjusted to the operator’s easy-to-use settings.

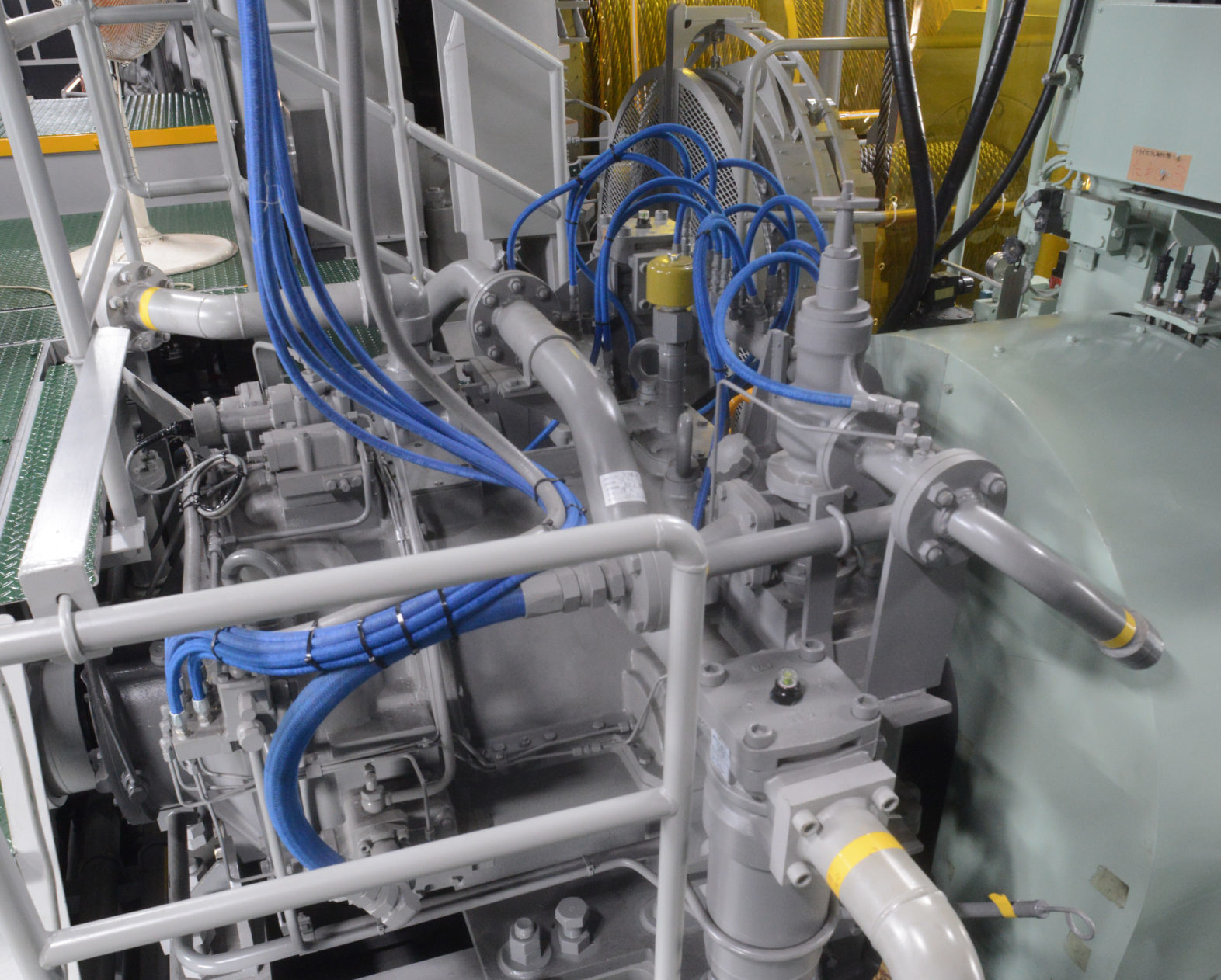

Torque Converter with Omega Clutch

SKK’s proprietary torque converter. Electronic control provides powerful, smooth operation and delicate speed control. Corresponding to the weight of the dredging amount, the speed of winding up is automatically changed to fit with the lifting load, the impact during operation is eased and smooth, stress-free operability is achieved.

Case Study

-

LC70-15GT (Line Pull 70ton / 15cbm)

Casablanca, Morocco

LC70-15GT Delivered March, 2021

Main Options

GPS Grab Dredging Engineering Management System

On the monitor of this system the dredging spot and depth can be checked in real time. By setting working spot in advance, the progress of dredging work is confirmed through the monitor which enables operations accurate without waste. Moreover, the work done is recorded, which is useful for making retrospections and reports

Flat-Dredging Control System, Depth Meter/Grab Bucket Open-Closing Degree Meter

The flat-dredging control system, developed by SKK in 1989, is a control system that by control the sinking degree of grab bucket so as to make the dredged trace on sea bottom near flat surface less of roughness. The sinking degree is automatically detected and controlled by the system and succeeded in significantly reducing dredging sediment residue. Quick and high-precision dredging work is now possible. The depth meter is an instrument that enables automatic deceleration and stop of grab bucket at a specified depth. There is not any more wire rope is reeled out after grab getting to the bottom so that the working time is shortened. In addition, the grab bucket opening degrees meter helps operator understand grab bucket opening degrees within from 0% to 100%.

Hook Pocket

Hook pocket is used to store and fasten an unused hook. This makes it possible to do grab dredging work without removing the hook. It leads to shorten the working time.